Packaging performance of power NTC thermistor

The packaging material of the resistor body has a great influence on the performance of the thermistor products. Packaging materials include silicone resin and phenolic resin; wires include CU wire and CP wire.

From the perspective of the steady-state current of the product, the phenolic resin product of the CP line is lower than the silicone product of the CU line, and the larger the diameter of the product, the more obvious the difference. The steady-state current of phenolic resin products of CP line is only 80-95% of that of silicone resin products of CU line.

From the perspective of the performance of the product from the 4 combinations of 2 kinds of encapsulating materials and 2 kinds of wires, the order from high to low is as follows:

CU wire & silicone resin, CU wire & phenol resin, CP wire & silicone resin, CP wire & phenol resin

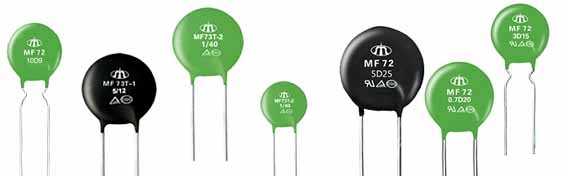

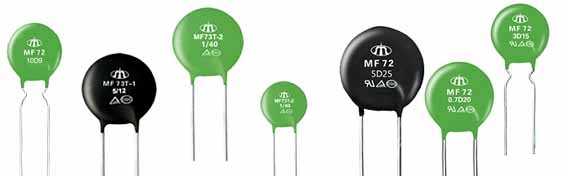

YAXUN Electronics' power NTC thermistors include MF72, MF73, MF73-1, MF73-2, MF73-3, MF74 series, complete series and many specifications. Strong surge current suppression capability, high impulse capacitance, and outstanding lightning protection capability. The products have passed UL, CUL, TUV, CQC safety certification. The minimum nominal resistance (R25) can reach 0.2Ω; the maximum steady-state current can reach 80A, and the maximum chip diameter is 50mm.

Power NTC thermistor is used to suppress surge current. When energized, the NTC thermistor is in a cold state and has a relatively large resistance value. By absorbing the heat generated by the surge pulse current flowing through the resistor, the work of the current is converted into heat energy. Under the dual action of surge pulse current and working current, the temperature of the NTC thermistor will rise, and the resistance value will drop sharply at the same time. After completing the function of suppressing the surge current, its own resistance (residual resistance) has been reduced to a very small extent due to the continuous effect of its current (steady-state current), and its power consumption has been negligible. Will not affect the normal operating current. Therefore, it is widely used to suppress the surge current of electronic equipment starting up.

Switching power supplies, transformers, chargers and other electrical equipment will generate instantaneous surge current when they are powered on. The greater the power, the higher the surge current. Inrush current can cause breaker damage, failure of protection components, and malfunction of equipment. Connecting the power NTC thermistor in series in the power circuit can effectively suppress the startup surge current and protect the electronic components.

1. Silicone resin and phenolic resin:

The temperature resistance of silicone resin is 200°C, the temperature resistance of phenolic resin is 130°C, and the heat dissipation performance of silicone resin is better. It is helpful for the chip to suppress the surge current and quickly dissipate the absorbed heat instantly. Thereby reducing the damage to the tin layer between the chip, the silver surface and the lead due to the high heat generated by the instantaneous surge current. Thereby greatly improving the service life of the chip itself. The price of phenolic resin is much lower than that of silicone resin.2. CU line and CP line:

The conductivity of the CP line is worse than that of the CU line, and the current capacity of the CP line is far inferior to that of the CU line. CU wire has better thermal conductivity, which can make the surface temperature of the product lower. The price of CP line is much lower than CU line.From the perspective of the steady-state current of the product, the phenolic resin product of the CP line is lower than the silicone product of the CU line, and the larger the diameter of the product, the more obvious the difference. The steady-state current of phenolic resin products of CP line is only 80-95% of that of silicone resin products of CU line.

From the perspective of the performance of the product from the 4 combinations of 2 kinds of encapsulating materials and 2 kinds of wires, the order from high to low is as follows:

CU wire & silicone resin, CU wire & phenol resin, CP wire & silicone resin, CP wire & phenol resin

YAXUN Electronics' power NTC thermistors include MF72, MF73, MF73-1, MF73-2, MF73-3, MF74 series, complete series and many specifications. Strong surge current suppression capability, high impulse capacitance, and outstanding lightning protection capability. The products have passed UL, CUL, TUV, CQC safety certification. The minimum nominal resistance (R25) can reach 0.2Ω; the maximum steady-state current can reach 80A, and the maximum chip diameter is 50mm.

Power NTC thermistor is used to suppress surge current. When energized, the NTC thermistor is in a cold state and has a relatively large resistance value. By absorbing the heat generated by the surge pulse current flowing through the resistor, the work of the current is converted into heat energy. Under the dual action of surge pulse current and working current, the temperature of the NTC thermistor will rise, and the resistance value will drop sharply at the same time. After completing the function of suppressing the surge current, its own resistance (residual resistance) has been reduced to a very small extent due to the continuous effect of its current (steady-state current), and its power consumption has been negligible. Will not affect the normal operating current. Therefore, it is widely used to suppress the surge current of electronic equipment starting up.

Switching power supplies, transformers, chargers and other electrical equipment will generate instantaneous surge current when they are powered on. The greater the power, the higher the surge current. Inrush current can cause breaker damage, failure of protection components, and malfunction of equipment. Connecting the power NTC thermistor in series in the power circuit can effectively suppress the startup surge current and protect the electronic components.