Heating power of PTC air heater

The heating power varies with heating time, as shown in Figure 9. At the beginning of power-on, the initial power is still relatively small (the initial power is usually 1/3 to 1/5 of the maximum impact power), then the heating power is gradually increased to the maximum impact power, then the power is decreased, and finally the stable power is reached. In the case of excessive heat dissipation, the heater is always at the initial power and cannot reach the maximum power, so the stable heating power is small.

Maximum impact power =C * Use voltage / normal temperature resistance

The value of the maximum impact power depends on the normal temperature resistance of the PTC ceramic heating sheet, the surface temperature, the grain size inside the ceramic body, the use voltage, and the like. Where the multiple C is 1~6, the higher the surface temperature of the PTC ceramic heating sheet, the larger C; The larger the room temperature resistance, the larger C will be. If there is a plurality of PTC ceramic heaters with different resistances in one heater, the maximum inrush current of the heater in the cold state (at room temperature) will be smaller; However, the hot state (at a temperature lower than the surface temperature of about 40 ° C) starts to be energized, and the maximum inrush current is large. The air heater with the largest impact power will stabilize the power slightly. If the maximum impact power is too large, it will affect the normal operation of the entire power supply circuit and switch; However, if the maximum impact power is too small, the heating power will not be required, and even if the blowing speed is larger, the heating power will be smaller.

The stable heating power of the PTC air heater is related to the wind speed. Generally speaking, the higher the wind speed, the faster the heat dissipation and the greater the heating power. Generally, the wind speed of the fan is 3~5m/s. The power without blowing is about 10% of the power at 5 m/s wind speed. The heating power can be adjusted by adjusting the wind speed when needed. If the impact power of the heater is close to the stable power at low wind speed, increasing the wind speed does not increase the power; Too much wind speed will reduce power.

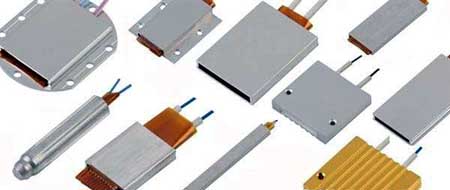

The non-insulated PTC air heater dissipates heat faster than the insulated type, so the heating power is also relatively large. The heat sink is denser, and the wind receiving area increases, which also increases heat dissipation, and the heating power increases. The number of PTC heating fins increases, and the stable heating power does not increase completely in proportion, and the heating power of each heater chip decreases.

The relationship between the heating power of PTC air heaters and the influencing factors is as follows:

Stable heating power = heat dissipation coefficient * (dry burning temperature - inlet air temperature)

The heating power is related to the inlet air temperature, and the higher the inlet air temperature, the smaller the stabilizing power. When the surface temperature of the PTC ceramic heating sheet is the same as the inlet air temperature, the heating power is substantially zero, that is, no heating is performed. Therefore, the surface temperature of the PTC ceramic heating sheet is always higher than the inlet air temperature of 20 ° C or higher, otherwise it cannot be heated. The smaller the difference between the surface temperature and the inlet air temperature of the PTC ceramic heating sheet, the smaller the heating power density, the larger the volume, and the higher the cost.

When the outlet air temperature of a heater cannot reach the required high temperature, to increase the outlet air temperature, a second PTC air heater needs to be placed along the wind direction. At this time, the first heater close to the fan has a higher power; The second heater away from the fan has a higher inlet air temperature, so the power is much lower and the stabilizing power is often less than 50% of the first heater.

The higher the surface temperature of the PTC ceramic heating sheet without air drying, the greater the heating power. However, the surface temperature of the PTC ceramic heating sheet is increased, the heating power is increased with the use time, the PTC heating sheet has an increased chance of breakdown, the performance of the adhesive, the electric wire, the insulating layer is lowered, the aluminum outer casing is loosened, and the reliability of the heater is lowered.