China PTC Ceramic Heating Sheet Supplier

- PRODUCT DETAIL

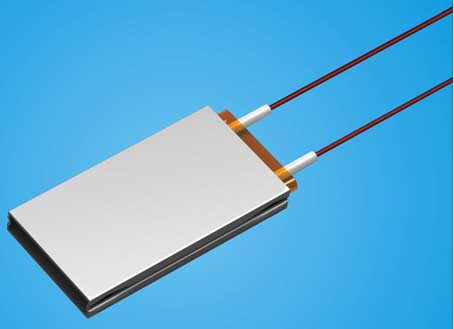

High temperature baking ceramic heating plate (MCH) is used to print resistance slurry directly on AL2O3 alumina ceramic green body. After being baked at a high temperature of about 1600 ° C, and then processed by electrodes and leads, a new generation of low and medium temperature heating elements are produced. It is another new generation after the alloy heating wire and PTC heating element. Widely used in daily life, industrial and agricultural technology, communication, medical, environmental protection, and other fields that require medium and low temperature heating.

In the field of household electric appliances:

Such as small warm air heater, hair dryer, clothes dryer, heater, cold and warm mobile phone, dryer, electric splint, electric iron, soldering iron, hair straightener, curling and perming device, electronic thermos bottle, insulation cabinet, electric cooker, toilet pottery heater, water heater, etc. In industry, such as industrial drying equipment, electrothermal adhesives, water-oil and acid-alkali liquid heaters, etc. In the electronic industry, such as small special crystal device thermostat; In medical applications such as infrared physiotherapy, intravenous injection heaters, etc.

With the advent of various electronic device integration eras, electronic complete machines have put forward higher requirements for circuit miniaturization, high density, versatility, high reliability, high speed and high power. Because the co-fired multi-layer ceramic substrate can meet the many requirements of the electronic whole machine, it has been widely used in recent years. The co-fired multilayer ceramic substrate can be classified into two types: a high temperature co-fired multilayer ceramic (HTCC) substrate and a low temperature co-fired multilayer ceramic (LTCC) substrate. Compared with low temperature co-fired ceramics, high temperature co-fired ceramics have the advantages of high mechanical strength, high wiring density, stable chemical properties, high heat dissipation coefficient and low material cost. It has been widely used in the fields of heating and packaging which require higher thermal stability, less high temperature volatile gas and higher sealing. HTCC ceramic heating sheets are mainly used to replace the most widely used alloy wire electric heating elements and PTC electric heating elements and their components. The alloy wire electric heating element has the disadvantages of high temperature, easy oxidation, short life, unsafe fire, low thermal efficiency, and uneven heating; The heating temperature of the PTC heating element is generally only about 200 °C. Lead tetroxide is commonly used when the heating temperature is higher than 120 °C. It is a eliminated product because of its high lead content.

product advantages

1. Simple structure;

2, Rapid temperature rise and fast temperature compensation;

3, High power density;

4, the heating temperature is high, up to 500 ° C or more;

5, high thermal efficiency, uniform heating, energy saving;

6, no open fire, safe to use;

7, long life, power loss reduction;

8, The heating element is insulated from the air, and the components are resistant to acid and alkali and other corrosive substances

Raw material

1, Substrate: white multi-layer alumina ceramic with а-Al2O3 content of not less than 95%

2, Lead wire: Nickel wire of Ф0.48mm is used.

3, casing, adhesive tape: Teflon, high temperature adhesive tape

4, resistance: high temperature materials such as tungste

Main performance

1, electrical performance

Insulation resistance: R≥5×108Ω [500VDC]

Rated applied voltage: 220VAC/110VAC

Resistance: R + 10% (23 + 1 ° C) or according to user contract requirements.

2, aging test: apply 110% of the rated voltage, a diode in series, on and off for 3 minutes for a cycle, a total of 2 cycles without abnormalities.

3. Voltage boost test: add 130VAC, 250VAC voltage, and connect a diode in series. The heating piece is energized for 10 seconds under each voltage without abnormality. [Applicable to 230VAC heating sheet]

4, thermal test: under normal voltage, the heating substrate is evenly heated, no abnormalities.

5, physical properties

Body density ≥ 3.6g/cm3

Bending strength ≥ 260MPa

6. Lead tension: the axial direction is not less than 5Kgf, and the angle between the axis and the axis is not less than 3Kgf.

7, temperature performance:

Operating temperature 100 ~ 230 ° C: The highest temperature can reach 500 ~ 700 ° C.

8, heating efficiency: up to 30 seconds to reach the working temperature.

9. Reliability: After 30 minutes of installation, the 30-minute meter is a cycle, and the test is normal after 1000 cycles.

Appearance

There is no mechanical damage burr, crack, rust and pollution in appearance, and its warpage is not more than 0.005mm/mm.

Product principle

Ceramic heating sheet, it is a kind of heating after the board is energized. A safe, reliable electric heating plate that is uncharged and has no open flame and is round or square in shape. The heating plate is mainly thermally conductive due to its use, so the thermal efficiency is high. Type of heating plate: It can be divided into thin shell type heating plate and cast plate type heating plate tubular element casting plate type electric heating plate.

PREVIOUS:NONE

NEXT:China PTC Heating Element Manufacturer

NEXT:China PTC Heating Element Manufacturer