Ntc thermistor selection

Proper selection of NTC thermistor/temperature sensors requires consideration of the following:

I. Learn about product application features:

1. Temperature measurement

2. Temperature compensation

3. Inrush current suppression

II. Classified by product application:

1. Automotive industry:

VT Series - Thermistors for Automotive Temperature Sensors

DTV Series - NTC Thermal Chip for Automotive Temperature Sensors

VTS Series - Vehicle Temperature Sensor / Temperature Switch

2. Medical industry:

MT Series - NTC Thermistors for Medical Device Temperature Sensors

DTM Series - NTC Thermal Chip for Medical Temperature Sensors

IT Series - Electronic Thermometer NTC Temperature Sensor

3. Home appliance industry:

TS Series - NTC Temperature Sensor

BT Series - Insulated Lead Type NTC Temperature Sensor

4. Communication industry:

CT Series - Chip Negative Temperature Coefficient Thermistor

AT Series - Non-insulated Lead Insert NTC Thermistor

5. Computer and office automation equipment:

OT Series - Office Automation NTC Thermistor / Temperature Sensor

GT Series - Glass Encapsulated NTC Thermistor

FT Series - Thin Film NTC Thermistors

6. Consumer Electronics:

PT Series - Power (Surge Suppression) NTC Thermistor

AT Series - Non-insulated Lead Insert NTC Thermistor

BT Series - Insulated Lead Type NTC Temperature Sensor

7. Integrated Circuits / Modules:

DT Series - High Precision Chip NTC Thermistor

III. Defining the product operating temperature range - corresponding to the choice of materials and packaging:

(1) Thermal head package form:

1. Epoxy resin package: moisture resistant, high dielectric strength, working temperature -40 ° C ~ +125 ° C

2. Silicone encapsulation: High dielectric strength, working temperature -40 ° C ~ +200 ° C, moisture resistance in general.

3. Glass package: moisture resistance, high insulation strength, high temperature resistance, working temperature -40 ° C ~ +350 ° C.

(2) Lead type:

1. Metal bare wire: Because there is no outer insulation skin, the working temperature depends on the temperature of the encapsulating material.

2. PVC electronic wire: Operating temperature -40 ° C ~ + (90-110) ° C.

3. Teflon electronic line: working temperature -40 ° C ~ +220 ° C.

4. Silicone electronic wire: Operating temperature -40 ° C ~ +250 ° C.

5. High temperature fluoroplastic line: Working temperature -40 ° C ~ +150 ° C.

IV. Define resistance value (zero power resistance value) RT and material constant-B value at design temperature

(1) Zero power resistance value RT (Ω)

The RT circuit design specifies the required resistance at temperature T.

The zero power resistance value refers to the resistance value measured by the measurement power that causes the resistance value change to be negligible with respect to the total measurement error.

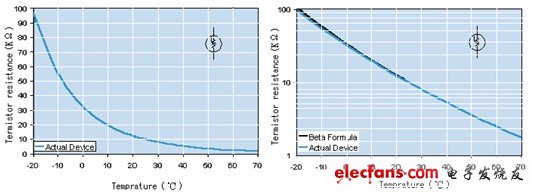

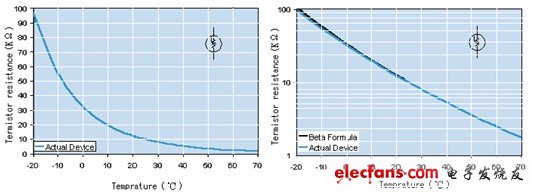

(2) Material constant - B value

Material constant (thermal index) B value (unit: Kelvin temperature K).

The image can be roughly understood as the slope of the NTC thermistor/temperature sensor that decreases with increasing temperature.

Determining the B value determines the resistance-temperature curve.

V. Determine the required response speed - thermal time constant τ

The thermal time constant τ is commonly referred to as the sensitivity of the NTC thermistor/temperature sensor sensing temperature.

Under zero power conditions, when the temperature is abrupt, the temperature of the thermistor body changes by 63.2% of the temperature difference between the temperature and the temperature.

Choose the right τ:

The τ value directly reflects the response speed of the NTC measurement temperature, but not as small as possible, and the τa value needs to be compared and traded off. Since the value of τ is related to its package size, the package size of NTC is small, the value of τa is small, and the mechanical strength is low; when the package size is large, the value of τa is large and the mechanical strength is high.

VI. Understanding the dissipation coefficient δ

That is: the ratio of the rate of change of the thermistor's dissipated power to its corresponding temperature change at a specified ambient temperature. It represents the power required to raise the thermal resistor by 1 °C. In the operating temperature range, δ varies with ambient temperature.

I. Learn about product application features:

1. Temperature measurement

2. Temperature compensation

3. Inrush current suppression

II. Classified by product application:

1. Automotive industry:

VT Series - Thermistors for Automotive Temperature Sensors

DTV Series - NTC Thermal Chip for Automotive Temperature Sensors

VTS Series - Vehicle Temperature Sensor / Temperature Switch

2. Medical industry:

MT Series - NTC Thermistors for Medical Device Temperature Sensors

DTM Series - NTC Thermal Chip for Medical Temperature Sensors

IT Series - Electronic Thermometer NTC Temperature Sensor

3. Home appliance industry:

TS Series - NTC Temperature Sensor

BT Series - Insulated Lead Type NTC Temperature Sensor

4. Communication industry:

CT Series - Chip Negative Temperature Coefficient Thermistor

AT Series - Non-insulated Lead Insert NTC Thermistor

5. Computer and office automation equipment:

OT Series - Office Automation NTC Thermistor / Temperature Sensor

GT Series - Glass Encapsulated NTC Thermistor

FT Series - Thin Film NTC Thermistors

6. Consumer Electronics:

PT Series - Power (Surge Suppression) NTC Thermistor

AT Series - Non-insulated Lead Insert NTC Thermistor

BT Series - Insulated Lead Type NTC Temperature Sensor

7. Integrated Circuits / Modules:

DT Series - High Precision Chip NTC Thermistor

III. Defining the product operating temperature range - corresponding to the choice of materials and packaging:

(1) Thermal head package form:

1. Epoxy resin package: moisture resistant, high dielectric strength, working temperature -40 ° C ~ +125 ° C

2. Silicone encapsulation: High dielectric strength, working temperature -40 ° C ~ +200 ° C, moisture resistance in general.

3. Glass package: moisture resistance, high insulation strength, high temperature resistance, working temperature -40 ° C ~ +350 ° C.

(2) Lead type:

1. Metal bare wire: Because there is no outer insulation skin, the working temperature depends on the temperature of the encapsulating material.

2. PVC electronic wire: Operating temperature -40 ° C ~ + (90-110) ° C.

3. Teflon electronic line: working temperature -40 ° C ~ +220 ° C.

4. Silicone electronic wire: Operating temperature -40 ° C ~ +250 ° C.

5. High temperature fluoroplastic line: Working temperature -40 ° C ~ +150 ° C.

IV. Define resistance value (zero power resistance value) RT and material constant-B value at design temperature

(1) Zero power resistance value RT (Ω)

The RT circuit design specifies the required resistance at temperature T.

The zero power resistance value refers to the resistance value measured by the measurement power that causes the resistance value change to be negligible with respect to the total measurement error.

(2) Material constant - B value

Material constant (thermal index) B value (unit: Kelvin temperature K).

The image can be roughly understood as the slope of the NTC thermistor/temperature sensor that decreases with increasing temperature.

Determining the B value determines the resistance-temperature curve.

V. Determine the required response speed - thermal time constant τ

The thermal time constant τ is commonly referred to as the sensitivity of the NTC thermistor/temperature sensor sensing temperature.

Under zero power conditions, when the temperature is abrupt, the temperature of the thermistor body changes by 63.2% of the temperature difference between the temperature and the temperature.

Choose the right τ:

The τ value directly reflects the response speed of the NTC measurement temperature, but not as small as possible, and the τa value needs to be compared and traded off. Since the value of τ is related to its package size, the package size of NTC is small, the value of τa is small, and the mechanical strength is low; when the package size is large, the value of τa is large and the mechanical strength is high.

VI. Understanding the dissipation coefficient δ

That is: the ratio of the rate of change of the thermistor's dissipated power to its corresponding temperature change at a specified ambient temperature. It represents the power required to raise the thermal resistor by 1 °C. In the operating temperature range, δ varies with ambient temperature.

VII. Determine product rated power Pn

The power that the thermistor allows for long-term continuous operation under specified technical conditions. At this power, the temperature of the resistor itself does not exceed its maximum operating temperature.

The power that the thermistor allows for long-term continuous operation under specified technical conditions. At this power, the temperature of the resistor itself does not exceed its maximum operating temperature.