NTC Sensor for Office Automation

- PRODUCT DETAIL

What Is The Office Automation Sensor

The printer has been able to achieve intelligent printing, on the one hand by the master chip, on the other hand rely on sensors distributed in all important parts of the printer also play a crucial role. Various operating state of the sensor is transmitted to the print CPU, so that the CPU can issue proper control commands, in order to ensure the normal operation of the printer. Thus ensuring the normal work of the printer, thin film NTC thermistor is the main sensor element of office automation sensor.

In Ya Xun, engaged in years of sensor development and research, to provide customers with customized sensors, including from the NTC, PTC chip sintering, slicing, packaging (glass seal, epoxy seal, film seal), plastic terminal injection molding and metal probe metal processing, to the temperature sensor assembly With the test, to meet the various customers of the sensor market development.

Characteristic

The contact surface of the elastic good, rapid response and high reliability.

It is most suitable to measure the surface temperature of the heat sink.

Working temperature: -20 ℃ ~ 230 ℃

Thermal time constant: ≤ 3S

Dissipation factor: 0.3mW / ℃ (in still air)

Wear resistance, low contact pressure, can reduce the damage to the roller.

Most suitable for color printing machine.

Standard types of office equipment sensor replication.

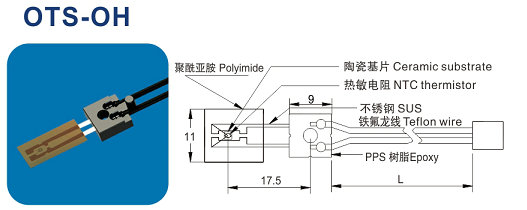

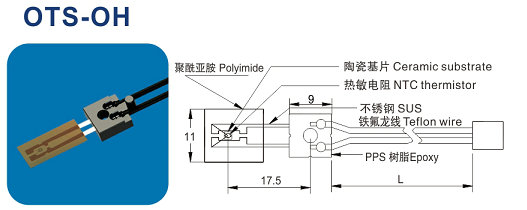

The constituent material of the sensor copier

Selection Parameters

Example - Troubleshooting The Fuser Fensor

Many office workers when operating the copier, are following this situation occurred. In the preheating time of the fixing roller of the copying machine, if the temperature reaches or exceeds the set temperature, fixing temperature abnormality occurs fault code on the display screen on the copier,

Then the copier to stop warming. In order to prevent the fixing temperature is too high can not control, causing the upper and lower fixing roller deformation, the failure code can not be used to restart the copier method to eliminate, we only have to remove the hardware failure or replace the fixing unit to enter the warm-up process.

Here we come to introduce how to lift the fixing failure method.

1.NP3100. 3200. 3300.2020 and other models

The fault code is shown in Table 1.

Remove the steps: Remove the side of the paper under the small cover, press the button inside the switch, then the display will appear OFF, and then turn off the power after 5S boot, fault code release.

2 .NP-7163/7214/7164 model

Fault code see Table II,

Release steps:

1, press the user key.

2, while pressing the number keys 2,8 to maintain more than 0.5S.

3, press the user key, the number screen "1".

4, press the number key "4" to display the hundred position.

5, press the AE key display screen display 3 digits, hundreds of flashing, ten and a bit bright spot.

6, press the number keys to enter 12, digital display "412".

7, press the copy button to confirm the clear.

8, shut down to restart the power, fault code release.

Printer Sensor Classification

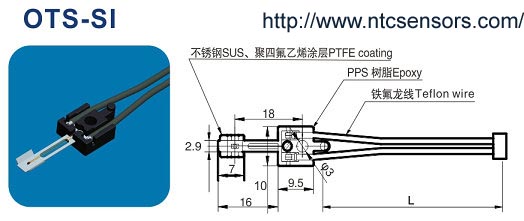

Contact type

The fixing assembly typically employing a contact type temperature sensor, the surface temperature of the fixing roller is sensed by the contact between the thermistor of the sensor and the fixing roller,

And the temperature reaches the required working state after the feedback information to the main circuit control board, so that the main circuit control board issues the next command to the fuser unit.

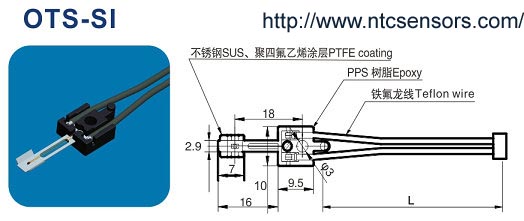

Non-contact

The non-contact temperature sensor detects the temperature in the middle of the hot roller and detects whether or not a loop break occurs by the infrared absorption film on the sensor. The standard is confirmed by detecting the temperature for the standard setting temperature comparison to confirm whether there is an abnormality. The following figure shows the non-contact temperature sensor:

Application

Copiers, printers, laser printers, multimedia equipment and laminating machines

Precautions for use

1). Do not bend the resistance wire frame to avoid causing the chip and the cable off and causing poor resistance;

2). Welding temperature should not exceed 300 ℃, the welding time is best not to exceed 0.5 seconds;

3). Heat shrink tubing when using hot air gun, air gun temperature should be controlled at about 120 ℃;

4). The use of constant temperature soldering iron, iron head flat, one hand to take the resistance, one hand to take the wire to touch welding, can improve production efficiency and shorten the welding time;

5). Special Note: Do not touch the chip (ie, the top of the resistor);

6). Product testing standards: Please refer to the thermistor test standard.

The printer has been able to achieve intelligent printing, on the one hand by the master chip, on the other hand rely on sensors distributed in all important parts of the printer also play a crucial role. Various operating state of the sensor is transmitted to the print CPU, so that the CPU can issue proper control commands, in order to ensure the normal operation of the printer. Thus ensuring the normal work of the printer, thin film NTC thermistor is the main sensor element of office automation sensor.

In Ya Xun, engaged in years of sensor development and research, to provide customers with customized sensors, including from the NTC, PTC chip sintering, slicing, packaging (glass seal, epoxy seal, film seal), plastic terminal injection molding and metal probe metal processing, to the temperature sensor assembly With the test, to meet the various customers of the sensor market development.

Characteristic

The contact surface of the elastic good, rapid response and high reliability.

It is most suitable to measure the surface temperature of the heat sink.

Working temperature: -20 ℃ ~ 230 ℃

Thermal time constant: ≤ 3S

Dissipation factor: 0.3mW / ℃ (in still air)

Wear resistance, low contact pressure, can reduce the damage to the roller.

Most suitable for color printing machine.

Standard types of office equipment sensor replication.

The constituent material of the sensor copier

| 1 | Polyimide film | width:12MM |

| 2 |

Glass sealing resistance

|

GT3K700H200C4500A |

| 3 |

Glass sealing resistance

|

GT3K300H0100C3930A |

| 4 | Aluminum foil | Aluminum foil ¢6.0*T0.06 |

| 5 | casing | Polyimide casing ¢6.0mm,长15mm |

| 6 | Silicone block | 11*11*T7mm Orange red |

| 7 | Silica gel | White silica gel |

| 8 | circuit board | Transparent circuit board 31*15.5*T1.0 |

| 9 | wire | UL1332#26AWG*1C TS 7/0.16 yellow |

| 10 | wire | UL1332#26AWG*1C TS 7/0.16 White |

| 11 | Silicone casing | White silicone sleeve ¢4.0 |

| 12 | Terminal | AMP179609-1 |

| 13 | Connector | AMP179228-4 |

Selection Parameters

| Part No. | Electronic Parameter |

| OTS-OL-1 | R25=364KΩ±5% B25/85=3370K±3% B100/200=3538K±3% |

| OTS-OL-2 | R200=4KΩ±5% B25/85=4557K±3% B100/200=4875K±3% |

| OTS-OL-3 | R200=3.7KΩ±5% B25/85=4640K±3% B100/200=5108K±3% |

| OTS-OL-4 | R200=1KΩ±5% B25/85=4253K±3% B100/200=4535K±3% |

| OTS-OL-5 | R200=3.3KΩ±5% B25/85=3966K±3% B100/200=4353K±3% |

Example - Troubleshooting The Fuser Fensor

Many office workers when operating the copier, are following this situation occurred. In the preheating time of the fixing roller of the copying machine, if the temperature reaches or exceeds the set temperature, fixing temperature abnormality occurs fault code on the display screen on the copier,

Then the copier to stop warming. In order to prevent the fixing temperature is too high can not control, causing the upper and lower fixing roller deformation, the failure code can not be used to restart the copier method to eliminate, we only have to remove the hardware failure or replace the fixing unit to enter the warm-up process.

Here we come to introduce how to lift the fixing failure method.

1.NP3100. 3200. 3300.2020 and other models

The fault code is shown in Table 1.

Remove the steps: Remove the side of the paper under the small cover, press the button inside the switch, then the display will appear OFF, and then turn off the power after 5S boot, fault code release.

| error code | cause of issue |

| E000 | When the printer is turned on within 1 minute, the thermistor detects the hardware temperature <100 ° C |

| E001 |

After the copier is turned on, the thermistor detects the fixing roller temperature> 200 ℃

|

| E004 | After the copy is turned on, the system detects the fuser roller thermistor off 3S, and the SSR turns on the output continuously> 3S |

2 .NP-7163/7214/7164 model

Fault code see Table II,

Release steps:

1, press the user key.

2, while pressing the number keys 2,8 to maintain more than 0.5S.

3, press the user key, the number screen "1".

4, press the number key "4" to display the hundred position.

5, press the AE key display screen display 3 digits, hundreds of flashing, ten and a bit bright spot.

6, press the number keys to enter 12, digital display "412".

7, press the copy button to confirm the clear.

8, shut down to restart the power, fault code release.

| error code | cause of issue |

| E000 | Copier after the power supply 14S, the thermistor detection on the fixed roller surface temperature <40 ℃ |

| E001 | After the copier is powered, the thermistor detects the surface temperature of the fixing roller> 230 ° C |

| E002 | Thermistor check on the surface of the fuser roller over 40 ℃, after four consecutive 10S seconds <60,80,100,120 ℃ |

| E003 | Standby speed of the fixed roller surface temperature reaches the target temperature of 160 ℃, due to fixing lamp or thermistor failure reasons, the thermistor detects the temperature of the fixing roller <130 ° C |

Printer Sensor Classification

Contact type

The fixing assembly typically employing a contact type temperature sensor, the surface temperature of the fixing roller is sensed by the contact between the thermistor of the sensor and the fixing roller,

And the temperature reaches the required working state after the feedback information to the main circuit control board, so that the main circuit control board issues the next command to the fuser unit.

Non-contact

The non-contact temperature sensor detects the temperature in the middle of the hot roller and detects whether or not a loop break occurs by the infrared absorption film on the sensor. The standard is confirmed by detecting the temperature for the standard setting temperature comparison to confirm whether there is an abnormality. The following figure shows the non-contact temperature sensor:

Application

Copiers, printers, laser printers, multimedia equipment and laminating machines

Precautions for use

1). Do not bend the resistance wire frame to avoid causing the chip and the cable off and causing poor resistance;

2). Welding temperature should not exceed 300 ℃, the welding time is best not to exceed 0.5 seconds;

3). Heat shrink tubing when using hot air gun, air gun temperature should be controlled at about 120 ℃;

4). The use of constant temperature soldering iron, iron head flat, one hand to take the resistance, one hand to take the wire to touch welding, can improve production efficiency and shorten the welding time;

5). Special Note: Do not touch the chip (ie, the top of the resistor);

6). Product testing standards: Please refer to the thermistor test standard.