Motor delay start up PTCR thermistor

- PRODUCT DETAIL

When a voltage is applied to the PTCR, a large current I begins to flow. After a certain period of time ts, as the temperature of the PTCR increases, the resistance value increases rapidly, resulting in a sharp drop in current. This period of time ts can be from 0.1s to several seconds, and its value depends on the thermal capacity, resistance value, thermal dissipation conditions, load resistance and operating voltage of the PTCR. When the external voltage is removed, the PTCR will cool to the normal temperature resistance value. Utilizing this principle, it has been widely used in starting electric motors for household refrigerators and air conditioners. It should be noted that when using the delay performance of PTCR, if the same delay time is to be repeated, a certain time tr (so-called recovery time) should be interval to restore the PTCR to the original state temperature, so it should avoid repeating the action immediately. Otherwise, the PTCR cannot provide a continuous high current, which will cause the compressor to fail to start normally and cause the compressor to burn out.

I. Overview

Single-phase induction motor driven compressor (such as refrigerators and air conditioners and other appliances),You can add an auxiliary winding in the starting circuit,Effective start. When the motor is running properly after the auxiliary winding to save energy.The PTC thermistor is used for this purpose.

When the motor starts,To overcome their inertia,But also to overcome the reaction of the load (such as the refrigerator compressor must be overcome when starting the reaction of the refrigerant) Therefore, the motor requires a large current and torque.When the rotation is normal,In order to save energy,The required torque and a substantial decline.To the motor plus a set of auxiliary coil,Only work at startup,Normal after it off.The PTC thermistor is connected in series to start the auxiliary coil,After starting PTC thermistor high-impedance state cut off the auxiliary coil, Just can achieve this effect.

The product has non-contact, low noise,High reliability, long life and other characteristics,Different characteristics,Structure to ensure different machine design requirements.

1. PTC thermistor for compressor start-up

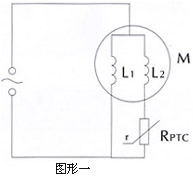

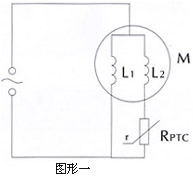

The compressor of the refrigerator is driven by a single-phase induction motor.When the motor starts,It is necessary to overcome their inertia,But also to overcome the load - the reaction of high-pressure refrigerant,Need to ensure a larger starting current,To this end, usually with a PTC thermistor startup circuit (schematic diagram shown in Figure 1).

2. Inverter air conditioner start with PTC thermistor

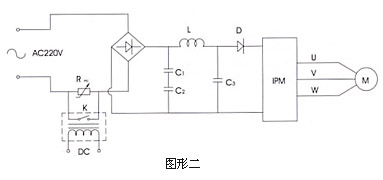

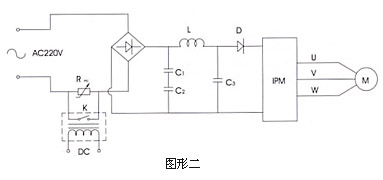

Inverter air conditioner starts,The voltage is added to the rectifying and filtering circuit through the PTC element,A smooth charging of the capacitor to the set value,Power module IPM begins to work,The input of the DC voltage into three alternating current added to the three-phase AC motor windings,So that the normal operation of the motor.While charging the capacitor to the set value,The IPM output a DC voltage to the relay pull switch K,PTC element is terminated,Suspension of work (see Figure II).

The purpose of series connection of PTC elements in the main circuit is:To avoid power in the early,Rectifier filter circuit directly withstand the impact of high current,Resulting in energy storage components damaged.That PTC components in the early power from the beginning of a buffer and the role of protection.In addition, if the relay fails (can not properly pull)PTC element after power becomes high impedance state,The circuit can be protected.

Product Size Chart:

I. Overview

Single-phase induction motor driven compressor (such as refrigerators and air conditioners and other appliances),You can add an auxiliary winding in the starting circuit,Effective start. When the motor is running properly after the auxiliary winding to save energy.The PTC thermistor is used for this purpose.

When the motor starts,To overcome their inertia,But also to overcome the reaction of the load (such as the refrigerator compressor must be overcome when starting the reaction of the refrigerant) Therefore, the motor requires a large current and torque.When the rotation is normal,In order to save energy,The required torque and a substantial decline.To the motor plus a set of auxiliary coil,Only work at startup,Normal after it off.The PTC thermistor is connected in series to start the auxiliary coil,After starting PTC thermistor high-impedance state cut off the auxiliary coil, Just can achieve this effect.

The product has non-contact, low noise,High reliability, long life and other characteristics,Different characteristics,Structure to ensure different machine design requirements.

1. PTC thermistor for compressor start-up

The compressor of the refrigerator is driven by a single-phase induction motor.When the motor starts,It is necessary to overcome their inertia,But also to overcome the load - the reaction of high-pressure refrigerant,Need to ensure a larger starting current,To this end, usually with a PTC thermistor startup circuit (schematic diagram shown in Figure 1).

2. Inverter air conditioner start with PTC thermistor

Inverter air conditioner starts,The voltage is added to the rectifying and filtering circuit through the PTC element,A smooth charging of the capacitor to the set value,Power module IPM begins to work,The input of the DC voltage into three alternating current added to the three-phase AC motor windings,So that the normal operation of the motor.While charging the capacitor to the set value,The IPM output a DC voltage to the relay pull switch K,PTC element is terminated,Suspension of work (see Figure II).

The purpose of series connection of PTC elements in the main circuit is:To avoid power in the early,Rectifier filter circuit directly withstand the impact of high current,Resulting in energy storage components damaged.That PTC components in the early power from the beginning of a buffer and the role of protection.In addition, if the relay fails (can not properly pull)PTC element after power becomes high impedance state,The circuit can be protected.

Product Size Chart:

| model | Nominal resistance | Switching temperature | Maximum voltage | Maximum current | Start Time | Power consumption | Recovery Time | Coil resistance | size | |

| R25(Ω) | Tb(℃) | Vmax(V) | Imax(A) | T0(S) | Pmax(W) | Trmax() | Rref(Ω) | D(mm) | T(mm) | |

| SPMZ8-3R3M160 | 3.3 | 120±10 | 160 | 12 | 0.3-1.2 | 3.5 | 100 | 10 | 20.0±1.0 | 2.5±0.2 |

| SPMZ8-3R9M160 | 3.9 | 160 | 12 | 0.3-1.2 | 3.5 | 100 | 10 | |||

| SPMZ8-4R7M180T2 | 4.7 | 180 | 12 | 0.3-1.2 | 3.5 | 100 | 10 | |||

| SPMZ8-5R6M180T2 | 5.6 | 180 | 12 | 0.3-1.2 | 3.5 | 100 | 10 | |||

| SPMZ8-6R8M220 | 6.8 | 220 | 10 | 0.3-1.2 | 3.5 | 100 | 15 | |||

| SPMZ8-10RM240 | 10 | 240 | 10 | 0.2-1.0 | 3.5 | 90 | 15 | |||

| SPMZ8-15RM260 | 15 | 260 | 10 | 0.2-1.0 | 3.5 | 90 | 25 | |||

| SPMZ8-22RM300 | 22 | 300 | 9 | 0.2-1.0 | 3 | 90 | 25 | |||

| SPMZ8-33RM300 | 33 | 300 | 9 | 0.2-1.0 | 3 | 90 | 25 | |||

| SPMZ8-47RM300 | 47 | 300 | 9 | 0.2-1.0 | 3 | 90 | 25 | |||

| SPMZ8-68RM320 | 68 | 320 | 9 | 0.2-1.0 | 3 | 90 | 25 | |||

| SPMZ8-4R7M170 | 4.7 | 120±10 | 170 | 12 | 0.2-1.0 | 3.5 | 85 | 10 | 17.5±1.0 | 2.5±0.2 |

| SPMZ8-5R6M190 | 5.6 | 190 | 12 | 0.2-1.0 | 3.5 | 85 | 10 | |||

| SPMZ8-6R8M220 | 6.8 | 220 | 10 | 0.2-1.0 | 3.5 | 85 | 15 | |||

| SPMZ8-10RM240 | 10 | 240 | 9 | 0.2-1.0 | 3.5 | 85 | 20 | |||

| SPMZ8-15RM260 | 15 | 260 | 8 | 0.2-1.0 | 3.5 | 85 | 20 | |||

| SPMZ8-22RM280 | 22 | 280 | 8 | 0.2-1.0 | 3.5 | 85 | 15 | |||

| SPMZ8-33RM280 | 33 | 280 | 7 | 0.2-1.0 | 3 | 85 | 20 | |||

| SPMZ8-47RM300 | 47 | 300 | 6 | 0.2-1.0 | 3 | 85 | 20 | |||

| SPMZ8-68RM300 | 68 | 300 | 5 | 0.2-1.0 | 3 | 85 | 20 | |||

| SPMZ8-3R3M160 | 3.3 | 135±10 | 160 | 12 | 0.3-1.2 | 3.5 | 80 | 10 | 20.0±1.0 | 2.5±0.2 |

| SPMZ8-3R9M160 | 3.9 | 160 | 12 | 0.3-1.2 | 3.5 | 80 | 10 | |||

| SPMZ8-4R7M180TG | 4.7 | 180 | 12 | 0.3-1.2 | 3.5 | 80 | 10 | |||

| SPMZ8-5R6M180TG | 5.6 | 180 | 12 | 0.3-1.2 | 3.5 | 80 | 10 | |||

| SPMZ8-6R8M200TG | 6.8 | 200 | 10 | 0.3-1.2 | 3.5 | 80 | 15 | |||

| SPMZ8-10RM230 | 10 | 230 | 9 | 0.45-1.35 | 3.2 | 70 | 15 | |||

| SPMZ8-15RM250 | 15 | 250 | 8 | 0.45-1.35 | 3.2 | 70 | 15 | |||

| SPMZ8-22RM300 | 22 | 300 | 7 | 0.45-1.35 | 3.2 | 70 | 20 | |||

| SPMZ8-33RM360 | 33 | 360 | 6 | 0.45-1.35 | 3.2 | 70 | 25 | |||

| SPMZ8-47RM400 | 47 | 400 | 5 | 0.45-1.35 | 3.2 | 70 | 35 | |||

| SPMZ8-68RM430 | 68 | 430 | 4 | 0.45-1.35 | 3.2 | 70 | 55 | 17.5±1.0 | 2.5±0.2 | |

| SPMZ8-4R7M180 | 4.7 | 135±10 | 180 | 10 | 0.3-1.2 | 3.4 | 90 | 15 | ||

| SPMZ8-5R6M180 | 5.6 | 180 | 10 | 0.3-1.2 | 3.4 | 90 | 15 | |||

| SPMZ8-6R8M200 | 6.8 | 200 | 9 | 0.3-1.2 | 3.4 | 90 | 15 | |||

| SPMZ8-10RM220 | 10 | 220 | 8 | 0.3-1.2 | 3.2 | 90 | 20 | |||

| SPMZ8-15RM240 | 15 | 240 | 7 | 0.2-1.0 | 3.2 | 80 | 20 | |||

| SPMZ8-22RM280 | 22 | 280 | 6 | 0.2-1.0 | 3.2 | 70 | 25 | |||

| SPMZ8-33RM320 | 33 | 320 | 4 | 0.2-1.0 | 3.2 | 70 | 45 | |||

| SPMZ8-47RM350 | 47 | 350 | 4 | 0.2-1.0 | 3.2 | 70 | 45 | |||

| SPMZ8-68RM400 | 68 | 400 | 4 | 0.2-1.0 | 3.2 | 70 | 45 | |||

| SPMZ8-4R7M160 | 4.7 |

135±10 |

160 | 10 | 0.4-1.5 | 3 | 90 | 15 | 16±1.0 | 2.5±0.2 |

| SPMZ8-5R6M170 | 5.6 | 170 | 10 | 0.4-1.5 | 3 | 90 | 15 | |||

| SPMZ8-6R8M180 | 6.8 | 180 | 9 | 0.4-1.5 | 3 | 90 | 15 | |||

| SPMZ8-10RM200 | 10 | 200 | 8 | 0.4-1.5 | 3 | 90 | 15 | |||

| SPMZ8-15RM230 | 15 | 230 | 7 | 0.4-1.5 | 3 | 80 | 20 | |||

| SPMZ8-22RM250 | 22 | 250 | 6 | 0.4-1.5 | 3 | 80 | 20 | |||

| SPMZ8-6R8M160 | 6.8 | 135±10 | 160 | 8 | 0.1-0.8 | 3 | 80 | 15 | 14±1.0 | 2.5±0.2 |

| SPMZ8-10RM180 | 10 | 180 | 7 | 0.1-0.8 | 3 | 80 | 20 | |||

| SPMZ8-15RM240 | 15 | 240 | 6 | 0.1-0.8 | 3 | 80 | 25 | |||

| SPMZ8-22RM240 | 22 | 240 | 5 | 0.1-0.8 | 3 | 70 | 25 | |||

| SPMZ8-33RM250 | 33 | 250 | 4 | 0.1-0.8 | 3 | 70 | 30 | |||