MF55 Thin film NTC thermistor Temperature measurement resistance

- PRODUCT DETAIL

MF55 Series Insulating Film Type NTC Thermistor

Product introduction

MF55 series insulation thin film NTC thermistor is the latest product developed by our company. It adopts a new process to produce, its structure is novel, its reliability is high, and its consistency is good. It is widely used in temperature testing, temperature control and temperature compensation. 2. Applications: Computers, printers, household appliances, etc.

3. Features: ·

Insulated thin film package, fast thermal induction speed, high sensitivity;

· Good stability and high reliability; ·

Good insulation;

· High resistance value accuracy; · Safe to use; · Small size, light weight, sturdy structure, easy for automated installation.

4. Main technical parameters ·

Rated zero power resistance (R25): 10KΩ to 100KΩ; ·

R25 Allowable deviation: ± 1%; ± 2%; ± 3%; ± 5%;

B value range (B25 / 50): 3380K; 3950K; ·

Allowable deviation of B value: ± 0.5%; ± 1%; ± 2%;

Dissipation coefficient: 0.7mW / ℃ (in still air); ·

Thermal time constant: ≤5S (in still air); ·

Operating temperature range: -30 ~ + 125 ℃ · Rated power: <3. 5mW5.

Product mark description:

① MF55 Insulation Film Thermistor

② Resistance: 103 …… 10KΩ

③ F: ± 1%; G: ± 2%; H: ± 3%; J: ± 5%;

④ B value: 3380K; 3950K ⑤ lead length: L: 15mm; 25mm; 50mm.

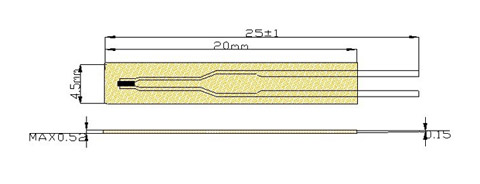

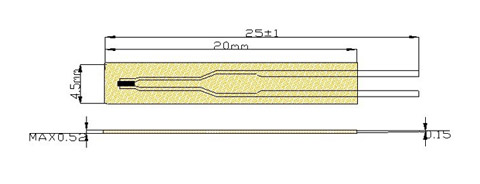

Dimensions: Code Specifications and Materials

① Polyammonium membrane ② Wafer ③ Phosphor bronze frame 6. Dimension drawing:

7. Matters needing attention:

1). Do not bend the resistance wire frame arbitrarily, so as to cause the chip and the wire frame to fall off and cause poor resistance;

2). The temperature during welding should not exceed 300 ℃, and the welding time should not exceed 0.5 seconds;

3). Use a hot air gun when heat shrinking the sleeve. The temperature of the air gun should be controlled around 120 ℃.

4). Use a constant temperature soldering iron when soldering. The tip is flat, with one hand holding the resistor and the other hand holding the wire for bump welding, which can improve production efficiency and shorten the welding time;

5). Special Note: Do not touch the chip (ie the top of the resistor) with your hand!

MF5B series of products for the co-directional thin-film package type

Note: The total length of the size can do: 18MM, 25MM, 50MM, 75MM (customized according to customer requirements)

Second: Features:

1: MF5B series of products for the co-directional thin-film package type

2: insulation film packaging, thermal induction speed, high sensitivity

3: good stability and high reliability

4: good insulation

5: high precision resistance

6: small size, light weight, rugged, easy to install automatically

Three: product model description

MF 5B 103 F 3950

① ② ③ ④ ⑤

①MF ¬ - negative temperature coefficient (NTC) thermistor code.

② 5B - thin film thermistor.

③103 - thermistor nominal resistance, said the resistance of the nominal resistance: 10 × 103 (Ω).

F = ± 1%, G = ± 2%, H = ± 3%, J = ± 5% of the resistance value (accuracy)

⑤ 3950 - resistance of the thermal index (material coefficient) B value: 395 × 10 (K)

F = ± 1%, G = ± 2%, H = ± 3%, J = ± 5% of the resistance value (accuracy)

⑤ 3950 - resistance of the thermal index (material coefficient) B value: 395 × 10 (K)

MF5B series of products using Note:

1: Do not arbitrarily bend resistance wire frame, So as to avoid chip and cable off, Causing poor resistance

2: welding temperature should not exceed 300 ℃, Welding time is best not more than 0.5 seconds

3: thermal casing using hot air gun, Air gun temperature should be controlled at about 120 ℃

4: When welding using a constant temperature soldering iron, Tip flat, One hand to get resistance, One hand to wire touch welding, Can improve production efficiency and shorten the welding time

5: Special Note: Do not touch the chip hand (that is, resistive top)

Five: MF5B series model specifications

Product introduction

MF55 series insulation thin film NTC thermistor is the latest product developed by our company. It adopts a new process to produce, its structure is novel, its reliability is high, and its consistency is good. It is widely used in temperature testing, temperature control and temperature compensation. 2. Applications: Computers, printers, household appliances, etc.

3. Features: ·

Insulated thin film package, fast thermal induction speed, high sensitivity;

· Good stability and high reliability; ·

Good insulation;

· High resistance value accuracy; · Safe to use; · Small size, light weight, sturdy structure, easy for automated installation.

4. Main technical parameters ·

Rated zero power resistance (R25): 10KΩ to 100KΩ; ·

R25 Allowable deviation: ± 1%; ± 2%; ± 3%; ± 5%;

B value range (B25 / 50): 3380K; 3950K; ·

Allowable deviation of B value: ± 0.5%; ± 1%; ± 2%;

Dissipation coefficient: 0.7mW / ℃ (in still air); ·

Thermal time constant: ≤5S (in still air); ·

Operating temperature range: -30 ~ + 125 ℃ · Rated power: <3. 5mW5.

Product mark description:

① MF55 Insulation Film Thermistor

② Resistance: 103 …… 10KΩ

③ F: ± 1%; G: ± 2%; H: ± 3%; J: ± 5%;

④ B value: 3380K; 3950K ⑤ lead length: L: 15mm; 25mm; 50mm.

Dimensions: Code Specifications and Materials

① Polyammonium membrane ② Wafer ③ Phosphor bronze frame 6. Dimension drawing:

7. Matters needing attention:

1). Do not bend the resistance wire frame arbitrarily, so as to cause the chip and the wire frame to fall off and cause poor resistance;

2). The temperature during welding should not exceed 300 ℃, and the welding time should not exceed 0.5 seconds;

3). Use a hot air gun when heat shrinking the sleeve. The temperature of the air gun should be controlled around 120 ℃.

4). Use a constant temperature soldering iron when soldering. The tip is flat, with one hand holding the resistor and the other hand holding the wire for bump welding, which can improve production efficiency and shorten the welding time;

5). Special Note: Do not touch the chip (ie the top of the resistor) with your hand!

MF5B series of products for the co-directional thin-film package type

Note: The total length of the size can do: 18MM, 25MM, 50MM, 75MM (customized according to customer requirements)

Second: Features:

1: MF5B series of products for the co-directional thin-film package type

2: insulation film packaging, thermal induction speed, high sensitivity

3: good stability and high reliability

4: good insulation

5: high precision resistance

6: small size, light weight, rugged, easy to install automatically

Three: product model description

MF 5B 103 F 3950

① ② ③ ④ ⑤

①MF ¬ - negative temperature coefficient (NTC) thermistor code.

② 5B - thin film thermistor.

③103 - thermistor nominal resistance, said the resistance of the nominal resistance: 10 × 103 (Ω).

F = ± 1%, G = ± 2%, H = ± 3%, J = ± 5% of the resistance value (accuracy)

⑤ 3950 - resistance of the thermal index (material coefficient) B value: 395 × 10 (K)

F = ± 1%, G = ± 2%, H = ± 3%, J = ± 5% of the resistance value (accuracy)

⑤ 3950 - resistance of the thermal index (material coefficient) B value: 395 × 10 (K)

MF5B series of products using Note:

1: Do not arbitrarily bend resistance wire frame, So as to avoid chip and cable off, Causing poor resistance

2: welding temperature should not exceed 300 ℃, Welding time is best not more than 0.5 seconds

3: thermal casing using hot air gun, Air gun temperature should be controlled at about 120 ℃

4: When welding using a constant temperature soldering iron, Tip flat, One hand to get resistance, One hand to wire touch welding, Can improve production efficiency and shorten the welding time

5: Special Note: Do not touch the chip hand (that is, resistive top)

Five: MF5B series model specifications

| Model | Rated resistance value | B value | Operating temperature | |||

| R25 (KΩ) | Precision | (25/50℃) | (25/85℃) | Precision | (℃) | |

| (K) | ||||||

| MF55□502□3270A | 5 |

±1% ±2% ±3% ±5% |

3270 |

±1% ±2% |

-50~260 | |

| MF55□502□3470A | 5 | 3470 | ||||

| MF55□103□3380A | 10 | 3380 | ||||

| MF55□103□3435B | 10 | 3435 | ||||

| MF55□103□3470B | 10 | 3470 | ||||

| MF55□103□3950A | 10 | 3950 | ||||

| MF55□103□3975B | 10 | 3975 | ||||

| MF55□203□3950A | 20 | 3950 | ||||

| MF55□303□3950A | 30 | 3950 | ||||

| MF55□473□3950A | 47 | 3950 | ||||

| MF55□503□3950A | 50 | 3950 | ||||

| MF55□104□3950A | 100 | 3950 | ||||