How to measure the quality of thermistor?

The thermistor is divided into a negative temperature coefficient (NTC) thermistor and a positive temperature coefficient (PTC) thermistor.

The thermistor is a type of sensitive component and is divided into a positive temperature coefficient thermistor (PTC) and a negative temperature coefficient thermistor (NTC) according to the temperature coefficient. Typical characteristics of thermistors are temperature sensitive and exhibit different resistance values at different temperatures. The positive temperature coefficient thermistor (PTC) has a higher resistance value at higher temperatures. The negative temperature coefficient thermistor (NTC) has a lower resistance value at higher temperatures. They belong to the same semiconductor device.

But it should be noted that: The thermistor is not a semiconductor device under the item 85.41 of the tariff.

First test the resistance in the indoor environment, and then hold the product test to see if the resistance is small. If the change is normal, otherwise it is not normal.

Note: Special instruments should be used for accurate measurement during testing.

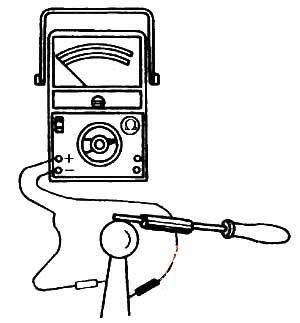

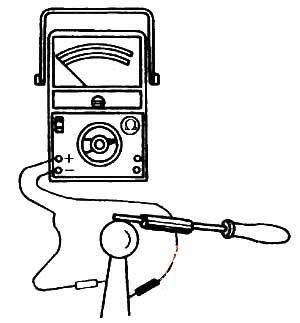

The heating method can be used to detect the quality of the thermistor, as shown in Figure 1. Use the multimeter's resistance file to connect the two leads of the thermistor, and then heat the thermistor (near the thermistor) with a hot soldering iron (20W). For PTC type thermistors, the resistance should increase as the temperature rises; for NTC type thermistors, the resistance should decrease as the temperature increases. If the thermistor is heated, its resistance does not change, indicating that the thermistor is damaged.

Detection of positive temperature coefficient thermistor (PTC)

When testing, use a multimeter R & TImes; The 1 gear, can be divided into two steps:

1. Normal temperature detection (indoor temperature is close to 25 ° C);

The two pins of the PTC thermistor are connected to the two pins to measure the actual resistance, and compared with the nominal resistance, the difference between the two is within ±2 Ω. If the actual resistance is too different from the nominal resistance, it indicates poor performance or damage.

2. Heating test; On the basis of the normal temperature test, the second test can be performed—heating detection, and a heat source (such as a soldering iron) is heated near the PTC thermistor. At the same time, use a multimeter to monitor whether the resistance value increases with the increase of temperature. If yes, the thermistor is normal. If the resistance did not change, indicating that the performance deterioration can not continue to use. Be careful not to get the heat source too close to or directly in contact with the PTC thermistor to prevent it from being burnt.

Detection of negative temperature coefficient thermistor (NTC)

1. Measure the nominal resistance value Rt:

The method of measuring the NTC thermistor with a multimeter is the same as the method of measuring the ordinary fixed resistor. That is, the actual value of Rt can be directly measured by selecting an appropriate electrical block according to the nominal resistance of the NTC thermistor. However, since the NTC thermistor is very sensitive to temperature, the following points should be noted when testing: ARt is measured by the manufacturer at an ambient temperature of 25 °C. Therefore, when measuring Rt with a multimeter, it should also be carried out when the ambient temperature is close to 25 °C to ensure the reliability of the test. B measurement power shall not exceed the specified value to avoid measurement error caused by current thermal effect. C pay attention to correct operation. When testing, do not hold the thermistor body with your hands to prevent the body temperature from affecting the test.

2. Estimate the temperature coefficient αt:

First, the resistance value Rt1 is measured at room temperature t1, and then the electric iron is used as a heat source, and the resistance value RT2 is measured near the thermistor Rt. At the same time, the average temperature t2 of the surface of the thermistor RT at this time is measured by a thermometer and then calculated.

The thermistor is a type of sensitive component and is divided into a positive temperature coefficient thermistor (PTC) and a negative temperature coefficient thermistor (NTC) according to the temperature coefficient. Typical characteristics of thermistors are temperature sensitive and exhibit different resistance values at different temperatures. The positive temperature coefficient thermistor (PTC) has a higher resistance value at higher temperatures. The negative temperature coefficient thermistor (NTC) has a lower resistance value at higher temperatures. They belong to the same semiconductor device.

But it should be noted that: The thermistor is not a semiconductor device under the item 85.41 of the tariff.

First test the resistance in the indoor environment, and then hold the product test to see if the resistance is small. If the change is normal, otherwise it is not normal.

Note: Special instruments should be used for accurate measurement during testing.

The heating method can be used to detect the quality of the thermistor, as shown in Figure 1. Use the multimeter's resistance file to connect the two leads of the thermistor, and then heat the thermistor (near the thermistor) with a hot soldering iron (20W). For PTC type thermistors, the resistance should increase as the temperature rises; for NTC type thermistors, the resistance should decrease as the temperature increases. If the thermistor is heated, its resistance does not change, indicating that the thermistor is damaged.

Figure 1 Using the heating method to detect the thermistor is good or bad

Measuring the resistance with a multimeter is a very basic task for engineers, and it is also a newcomer engineer who needs to master it. In today's knowledge sharing of multimeter resistance, we will share a basic knowledge of multimeter resistance measurement technology, that is, how to use a multimeter to test the quality of the thermistor components. Let's take a look at it below.Detection of positive temperature coefficient thermistor (PTC)

When testing, use a multimeter R & TImes; The 1 gear, can be divided into two steps:

1. Normal temperature detection (indoor temperature is close to 25 ° C);

The two pins of the PTC thermistor are connected to the two pins to measure the actual resistance, and compared with the nominal resistance, the difference between the two is within ±2 Ω. If the actual resistance is too different from the nominal resistance, it indicates poor performance or damage.

2. Heating test; On the basis of the normal temperature test, the second test can be performed—heating detection, and a heat source (such as a soldering iron) is heated near the PTC thermistor. At the same time, use a multimeter to monitor whether the resistance value increases with the increase of temperature. If yes, the thermistor is normal. If the resistance did not change, indicating that the performance deterioration can not continue to use. Be careful not to get the heat source too close to or directly in contact with the PTC thermistor to prevent it from being burnt.

Detection of negative temperature coefficient thermistor (NTC)

1. Measure the nominal resistance value Rt:

The method of measuring the NTC thermistor with a multimeter is the same as the method of measuring the ordinary fixed resistor. That is, the actual value of Rt can be directly measured by selecting an appropriate electrical block according to the nominal resistance of the NTC thermistor. However, since the NTC thermistor is very sensitive to temperature, the following points should be noted when testing: ARt is measured by the manufacturer at an ambient temperature of 25 °C. Therefore, when measuring Rt with a multimeter, it should also be carried out when the ambient temperature is close to 25 °C to ensure the reliability of the test. B measurement power shall not exceed the specified value to avoid measurement error caused by current thermal effect. C pay attention to correct operation. When testing, do not hold the thermistor body with your hands to prevent the body temperature from affecting the test.

2. Estimate the temperature coefficient αt:

First, the resistance value Rt1 is measured at room temperature t1, and then the electric iron is used as a heat source, and the resistance value RT2 is measured near the thermistor Rt. At the same time, the average temperature t2 of the surface of the thermistor RT at this time is measured by a thermometer and then calculated.