Function and Classification of Air-conditioning Temperature Sensors

Key words: indoor temperature sensor, indoor evaporator pipeline temperature sensor, condenser pipeline temperature sensor, compressor exhaust temperature sensor, fault detection of temperature sensor

Function and Classification of Air-conditioning Temperature Sensors

Type and function of air conditioning NTC temperature sensor.

1. Indoor temperature sensor

It is installed in the air inlet of the evaporator in the air conditioner, supported by plastic parts, and can be used to detect whether the indoor temperature reaches the set value. Its role is as follows.

1> Used to automatically control the indoor ambient temperature during heating or cooling.

2> used to control the operation of the auxiliary electric heater when heating.

2. Indoor evaporator pipeline temperature sensor. It is installed in the indoor evaporator pipeline. The outside is packed in metal tubes, which are in direct contact with the pipeline, so the temperature measured is close to the evaporation of the refrigeration system. Its function is as follows.

1> Process control during summer cooling. (Preventing insufficient refrigerant in the system or frosting in the indoor evaporator)

2> Used for anti-cold wind control during winter heating.

3> is used to control the speed of the indoor fan motor.

4> cooperate with the single-chip microcomputer to realize fault self-diagnosis.

5> assists in the defrosting of the outdoor unit during heating.

3. Outdoor ambient temperature sensor.

It is mounted on the outdoor unit radiator. Supported by plastic parts to detect outdoor ambient temperature. Its main role is as follows.

1> Used to control the speed of the outdoor fan motor during cooling or heating.

2> When the outdoor temperature is too low or too high, it is used to control the system for automatic protection.

4. Outdoor condenser line temperature sensor.

It is mounted on the radiator of outdoor machine and packed with metal pipes to detect the temperature of outdoor pipes. Its main functions are as follows.

1> When heating, it is used for defrosting of outdoor machines.

2> Refrigeration or heating for overheating protection or anti-freezing protection.

5. Outdoor unit compressor exhaust temperature sensor

It is installed on the exhaust pipe of outdoor compressor and packed with metal pipe. Its main functions are as follows.

1> When the temperature of the compressor exhaust pipe is too high, it is used for automatic protection of the control system.

2> In frequency converter air conditioner, it is used to control the opening degree of electronic expansion valve and the rise and fall of compressor operation frequency.

Fault detection of the air conditioner temperature sensor.

1. On-line Detection of Temperature Sensors.

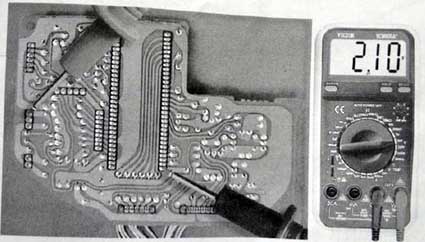

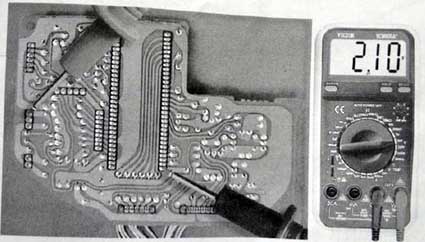

The PCB in the indoor main engine is removed from the fixed module, and then various components are connected. Turn on the power and check the temperature sensor of the air conditioner to see if the voltage it sends to the microprocessor is normal. It can judge whether the temperature sensor is good or not. It is worth noting that personal safety should be paid attention to when road detection is carried out.

Using multimeter to detect temperature sensor should be carried out at the solder joint on the back of the computer board. Ground the black test lead of the multimeter, connect the red test lead to the solder joint of the temperature sensor, and select the 20V voltage file for the multimeter's gear position. Under normal circumstances, the voltage sent by the indoor temperature sensor to the microprocessor should be about 2V. If the sensor is damaged, the measured voltage value is 0V. The voltage value sent to the microprocessor by the evaporator line temperature sensor should be about 3V. If the sensor is damaged, the measured value is 0V. When the measured sensing voltage value is 0V, the external sensor is damaged and should be replaced.

2. Open circuit detection of temperature sensor.

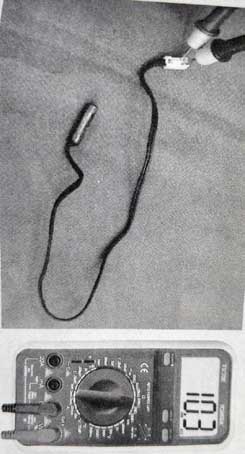

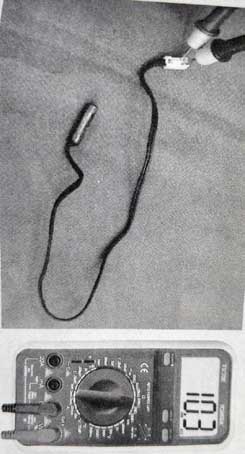

In addition to road detection, temperature sensors should also be open-circuit detection to measure their resistance under different temperature conditions. In this way, we can judge whether the temperature sensor is good or not. Detection methods, like on-line detection, are measured by multimeter.

The detection method is the same as the road detection, which is measured by a multimeter.

If the resistance value of the temperature sensor is always very large and tends to infinite, then the temperature sensor fails. If the open circuit detection of temperature sensor is normal, and the pin voltage value is too high or too low in the circuit detection, the circuit part should be further detected and troubleshooting.

Function and Classification of Air-conditioning Temperature Sensors

Type and function of air conditioning NTC temperature sensor.

1. Indoor temperature sensor

It is installed in the air inlet of the evaporator in the air conditioner, supported by plastic parts, and can be used to detect whether the indoor temperature reaches the set value. Its role is as follows.

1> Used to automatically control the indoor ambient temperature during heating or cooling.

2> used to control the operation of the auxiliary electric heater when heating.

2. Indoor evaporator pipeline temperature sensor. It is installed in the indoor evaporator pipeline. The outside is packed in metal tubes, which are in direct contact with the pipeline, so the temperature measured is close to the evaporation of the refrigeration system. Its function is as follows.

1> Process control during summer cooling. (Preventing insufficient refrigerant in the system or frosting in the indoor evaporator)

2> Used for anti-cold wind control during winter heating.

3> is used to control the speed of the indoor fan motor.

4> cooperate with the single-chip microcomputer to realize fault self-diagnosis.

5> assists in the defrosting of the outdoor unit during heating.

3. Outdoor ambient temperature sensor.

It is mounted on the outdoor unit radiator. Supported by plastic parts to detect outdoor ambient temperature. Its main role is as follows.

1> Used to control the speed of the outdoor fan motor during cooling or heating.

2> When the outdoor temperature is too low or too high, it is used to control the system for automatic protection.

4. Outdoor condenser line temperature sensor.

It is mounted on the radiator of outdoor machine and packed with metal pipes to detect the temperature of outdoor pipes. Its main functions are as follows.

1> When heating, it is used for defrosting of outdoor machines.

2> Refrigeration or heating for overheating protection or anti-freezing protection.

5. Outdoor unit compressor exhaust temperature sensor

It is installed on the exhaust pipe of outdoor compressor and packed with metal pipe. Its main functions are as follows.

1> When the temperature of the compressor exhaust pipe is too high, it is used for automatic protection of the control system.

2> In frequency converter air conditioner, it is used to control the opening degree of electronic expansion valve and the rise and fall of compressor operation frequency.

Fault detection of the air conditioner temperature sensor.

1. On-line Detection of Temperature Sensors.

The PCB in the indoor main engine is removed from the fixed module, and then various components are connected. Turn on the power and check the temperature sensor of the air conditioner to see if the voltage it sends to the microprocessor is normal. It can judge whether the temperature sensor is good or not. It is worth noting that personal safety should be paid attention to when road detection is carried out.

Using multimeter to detect temperature sensor should be carried out at the solder joint on the back of the computer board. Ground the black test lead of the multimeter, connect the red test lead to the solder joint of the temperature sensor, and select the 20V voltage file for the multimeter's gear position. Under normal circumstances, the voltage sent by the indoor temperature sensor to the microprocessor should be about 2V. If the sensor is damaged, the measured voltage value is 0V. The voltage value sent to the microprocessor by the evaporator line temperature sensor should be about 3V. If the sensor is damaged, the measured value is 0V. When the measured sensing voltage value is 0V, the external sensor is damaged and should be replaced.

2. Open circuit detection of temperature sensor.

In addition to road detection, temperature sensors should also be open-circuit detection to measure their resistance under different temperature conditions. In this way, we can judge whether the temperature sensor is good or not. Detection methods, like on-line detection, are measured by multimeter.

The detection method is the same as the road detection, which is measured by a multimeter.

If the resistance value of the temperature sensor is always very large and tends to infinite, then the temperature sensor fails. If the open circuit detection of temperature sensor is normal, and the pin voltage value is too high or too low in the circuit detection, the circuit part should be further detected and troubleshooting.