NTC Thermistor Chip Manufacturing Process

Ya Xun is committed to technological innovation, technology leadership industry development, at present, the company developed the chip type is the development of NTC thermistor direction, chip type can meet the miniaturization of electronic components, lightweight, thin, digitized, and versatile and assembly automation requirements. Our company has completed the commercialization of multilayer chip type thermistors.

(Mn), cobalt (Co), nickel (Ni), aluminum (Al), zinc (Zn) and other two or more high-purity metal oxide as the main material, the nanometer powder materials synthesized by co-precipitation or hydrothermal method, after the full mixing by the ball mill, Isostatic pressing forming, High temperature sintering, Semiconductor chips, Dicing, Glass sealing sintering or epoxy encapsulation and other sealing process made of close to the theoretical density of the structure of semiconductor electronic ceramic materials, these metal oxide materials have semiconductor properties,because the conductive way is completely similar to germanium, silicon and other semiconductor materials. It has a resistance value with the temperature changes and the corresponding changes in the characteristics.

Our company uses soft chemistry method widely used in electronic ceramic powder material production and research, including coprecipitation method, homogeneous precipitation method, sol gel method, hydrothermal method and so on. the resistivity and material parameters (B value) vary with the material composition ratio, sintering temperature, sintering atmosphere and structure. this thermistor with negative temperature coefficient has the characteristics of high sensitivity, good stability, fast response, long life and low cost.

For your next product development, please contact our enthusiastic thermistor technical team, we will give the most professional technical parameters and selection.

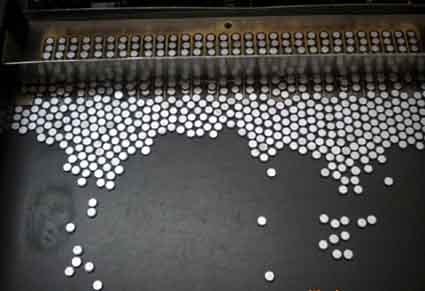

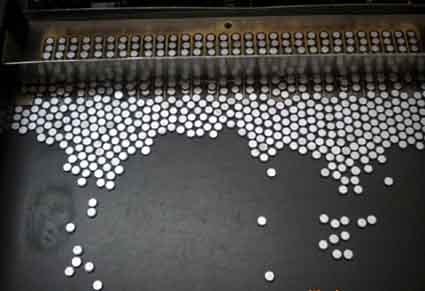

The Following Table Is the NTC Thermistor Chip Manufacturing Process

(Mn), cobalt (Co), nickel (Ni), aluminum (Al), zinc (Zn) and other two or more high-purity metal oxide as the main material, the nanometer powder materials synthesized by co-precipitation or hydrothermal method, after the full mixing by the ball mill, Isostatic pressing forming, High temperature sintering, Semiconductor chips, Dicing, Glass sealing sintering or epoxy encapsulation and other sealing process made of close to the theoretical density of the structure of semiconductor electronic ceramic materials, these metal oxide materials have semiconductor properties,because the conductive way is completely similar to germanium, silicon and other semiconductor materials. It has a resistance value with the temperature changes and the corresponding changes in the characteristics.

Our company uses soft chemistry method widely used in electronic ceramic powder material production and research, including coprecipitation method, homogeneous precipitation method, sol gel method, hydrothermal method and so on. the resistivity and material parameters (B value) vary with the material composition ratio, sintering temperature, sintering atmosphere and structure. this thermistor with negative temperature coefficient has the characteristics of high sensitivity, good stability, fast response, long life and low cost.

For your next product development, please contact our enthusiastic thermistor technical team, we will give the most professional technical parameters and selection.

The Following Table Is the NTC Thermistor Chip Manufacturing Process

| Process | equipment |

| Substrate | Single crystal furnace, slicing machine, grinding machine and so on |

| Epitaxial process (diffusion, sputtering, chemical vapor deposition) | Epitaxial furnace (MOCVD) |

| Lei wafer | washing machine |

| Cleaning | Steaming machine, electron gun |

| Vapor deposition | Baking, photoresist, photographic exposure, development |

| Yellow light operations | |

| Chemical etching | Etching machine |

| Fused | |

| Grinding | Thinning machine, washing machine |

| Cut | Cutting Machine |

| Test | Probe test bench, particle size detector |