Air conditioning PTC corrugated heater Global custom supply

The air conditioning PTC corrugated heater is a self-controlled temperature heater.

1. Constant temperature heating PTC thermistor has constant temperature heating characteristics. The principle is that PTC thermistor is heated by itself to make the resistance enter the jump zone, and the surface temperature of PTC thermistor will remain constant when heated at constant temperature. The temperature is only related to Curie temperature and applied voltage of PTC thermistor, but not to ambient temperature.

2. PTC heating element is a heating element designed by constant temperature heating PTC thermistor constant temperature heating characteristics. In the case of medium and small power heating, the PTC heating element has the advantages of constant temperature heating, no open flame, high heat conversion rate, minimal influence of power supply voltage, and long life expectancy. The application in electric heating appliances is increasingly favored by R&D engineers.

3. The constant temperature heating PTC thermistor can be made into a variety of shapes and specifications, and is commonly used in the form of a circular shape, a rectangular shape, a long strip shape, a ring shape, and a honeycomb porous shape. The combination of the above PTC heating element and the metal member can form various forms of high power PTC heating elements.

PTC heater application and precautions

1. Solid temperature heating.

1.1 Solid heater structure.

In the case of heat conduction of materials with large thermal conductivity (such as aluminum, copper, graphite, etc.), the distance S between the heated solid and the PTC heater should be within 30 mm; In the case of a material with a slightly higher thermal conductivity (such as steel, stainless steel, titanium, thermal ceramics, etc.), the distance between the heated solid and the PTC heater should be within 10 mm; In the case of heat conduction of materials with poor thermal conductivity (such as plastic, non-porous rubber, insulating paper, mica flakes, etc.), the distance between the heated solid and the PTC heater should be within 3 mm; Do not use thermal insulation materials (such as fiber paper, rubber, foam, etc.) to conduct heat. With a material with a good thermal conductivity, the distance between the heated solid and the PTC heater is small, and the heated solid will obtain a relatively stable temperature.

The ratio of the area of the heat dissipation structure to the heat transfer area of the PTC ceramic body is preferably not more than three times. The proportion of the area of the heat dissipating structure is too large, which makes the temperature obtained by the heated solid unstable.

1.2 Surface temperature.

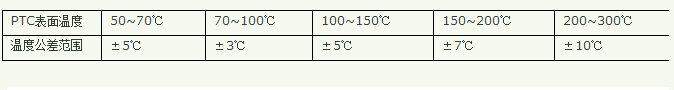

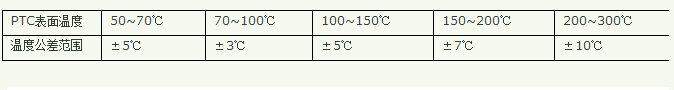

The temperature tolerance of the PTC ceramic heater is shown in Table 1 at an ambient temperature of 25 °C ± 5 °C. However, if the PTC ceramic heater is mounted in the heat dissipation structure, the temperature accuracy is deteriorated and the tolerance is increased. In the case where the heat transfer inside the heater is poor and the area of the heat dissipation structure is relatively large compared with the heat transfer area of the PTC ceramic body, the temperature accuracy is lowered.

Table 1.

There are many factors affecting the surface temperature of the PTC heater, so the accuracy of the surface constant temperature cannot be very high. In the case where high temperature control accuracy is required, a PTC heater can be used, plus a temperature controller. When the external temperature controller fails, the heating surface temperature of the PTC heater does not exceed the set constant temperature and has an over-temperature protection function.

1.3 Heating rate.

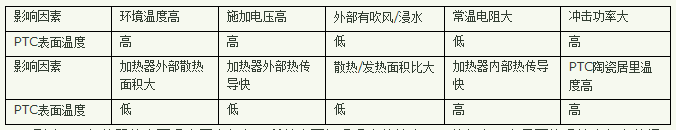

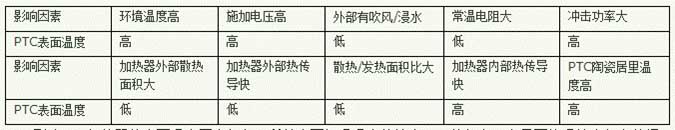

The factors affecting the heating rate of the PTC heater are shown in Table 3.

table 3.

1.4 Application occasion.

Electric mosquito repellent, massager, warmer, electric iron, electric iron, humidifier, curling iron, hair straightener, glue machine, Electric heaters, hot melt glue guns, electric irons, melting waxes, electronic components insulation, circuit board flooding, etc.

The PTC heater is used as a solid constant temperature heating, and the heating temperature is 0 to 300 ° C, and the heating temperature is 50 to 300 ° C at normal temperature. The adapted ambient temperature is -40~250 °C. PTCs with too high or too low surface temperatures are more difficult to manufacture and do not even have PTC characteristics.

The working voltage is 3.7V~420V, both AC and DC are acceptable. When the working voltage is low, the PTC's normal temperature resistance is small, the resistance-temperature change rate is also relatively small, and the constant temperature temperature accuracy is worse; In addition, at low voltages, the heating power is small, the heating rate is slow, and it is not even possible to rise to a higher temperature.

From the perspective of safety and reliability, PTC heaters generally have higher safety than traditional electric heating wires, high insulation voltage resistance, relatively small leakage current and relatively stable. In some applications, the use of traditional heating wire can not pass the safety certification, and the PTC heater can pass the safety certification, so PTC can be used in places with high safety requirements. However, not all manufacturers' PTCs, all PTCs, will meet the requirements for safety, so we must choose a high quality PTC production plant.

PTC is used for solid heating, the main safety and reliability issues:

(1) PTC ceramic breakdown and burning, resulting in short circuit, burning insulation layer;

(2) The insulating layer breaks down and leaks electricity to make the shell charged.

From the cost point of view, a small area of constant temperature heating, PTC heater can save the temperature control and over-temperature protection part, PTC volume can be done very small, the installation is relatively simple. Constant heating of large heating area, using PTC heater to heat the temperature more uniform. PTC thermostat heaters last several times longer than conventional heater heaters. The use of PTC also saves life and maintenance costs.

1. Constant temperature heating PTC thermistor has constant temperature heating characteristics. The principle is that PTC thermistor is heated by itself to make the resistance enter the jump zone, and the surface temperature of PTC thermistor will remain constant when heated at constant temperature. The temperature is only related to Curie temperature and applied voltage of PTC thermistor, but not to ambient temperature.

2. PTC heating element is a heating element designed by constant temperature heating PTC thermistor constant temperature heating characteristics. In the case of medium and small power heating, the PTC heating element has the advantages of constant temperature heating, no open flame, high heat conversion rate, minimal influence of power supply voltage, and long life expectancy. The application in electric heating appliances is increasingly favored by R&D engineers.

3. The constant temperature heating PTC thermistor can be made into a variety of shapes and specifications, and is commonly used in the form of a circular shape, a rectangular shape, a long strip shape, a ring shape, and a honeycomb porous shape. The combination of the above PTC heating element and the metal member can form various forms of high power PTC heating elements.

PTC heater application and precautions

1. Solid temperature heating.

1.1 Solid heater structure.

In the case of heat conduction of materials with large thermal conductivity (such as aluminum, copper, graphite, etc.), the distance S between the heated solid and the PTC heater should be within 30 mm; In the case of a material with a slightly higher thermal conductivity (such as steel, stainless steel, titanium, thermal ceramics, etc.), the distance between the heated solid and the PTC heater should be within 10 mm; In the case of heat conduction of materials with poor thermal conductivity (such as plastic, non-porous rubber, insulating paper, mica flakes, etc.), the distance between the heated solid and the PTC heater should be within 3 mm; Do not use thermal insulation materials (such as fiber paper, rubber, foam, etc.) to conduct heat. With a material with a good thermal conductivity, the distance between the heated solid and the PTC heater is small, and the heated solid will obtain a relatively stable temperature.

The ratio of the area of the heat dissipation structure to the heat transfer area of the PTC ceramic body is preferably not more than three times. The proportion of the area of the heat dissipating structure is too large, which makes the temperature obtained by the heated solid unstable.

1.2 Surface temperature.

The temperature tolerance of the PTC ceramic heater is shown in Table 1 at an ambient temperature of 25 °C ± 5 °C. However, if the PTC ceramic heater is mounted in the heat dissipation structure, the temperature accuracy is deteriorated and the tolerance is increased. In the case where the heat transfer inside the heater is poor and the area of the heat dissipation structure is relatively large compared with the heat transfer area of the PTC ceramic body, the temperature accuracy is lowered.

Table 1.

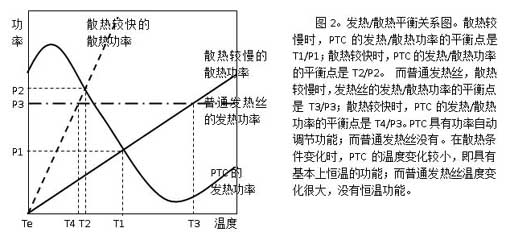

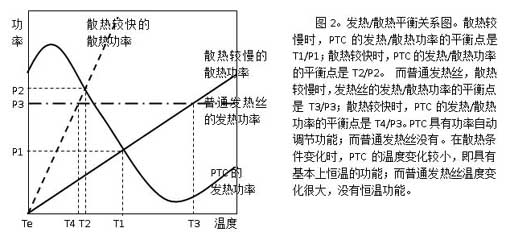

Figure 2 is a PTC heating/heat dissipation balance diagram.

The resistance value of the PTC heater increases sharply as its temperature rises. Therefore, when the temperature rises, the heating power will drop sharply; when the heating power and the heat dissipation power reach equilibrium, the temperature will no longer rise and the power will not change. However, when heat dissipation conditions (such as ambient temperature, blowing, water immersion, etc.) change, the power and temperature of the PTC are readjusted to reach a new balance.

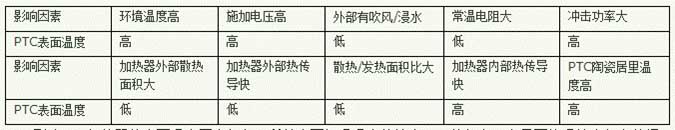

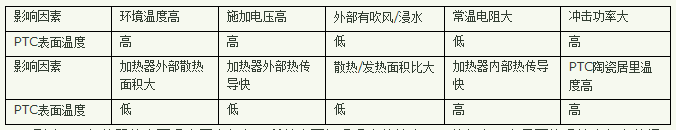

See Table 2 for the factors affecting the surface temperature of the PTC.

Table 2.

See Table 2 for the factors affecting the surface temperature of the PTC.

Table 2.

There are many factors affecting the surface temperature of the PTC heater, so the accuracy of the surface constant temperature cannot be very high. In the case where high temperature control accuracy is required, a PTC heater can be used, plus a temperature controller. When the external temperature controller fails, the heating surface temperature of the PTC heater does not exceed the set constant temperature and has an over-temperature protection function.

1.3 Heating rate.

The factors affecting the heating rate of the PTC heater are shown in Table 3.

table 3.

1.4 Application occasion.

Electric mosquito repellent, massager, warmer, electric iron, electric iron, humidifier, curling iron, hair straightener, glue machine, Electric heaters, hot melt glue guns, electric irons, melting waxes, electronic components insulation, circuit board flooding, etc.

The PTC heater is used as a solid constant temperature heating, and the heating temperature is 0 to 300 ° C, and the heating temperature is 50 to 300 ° C at normal temperature. The adapted ambient temperature is -40~250 °C. PTCs with too high or too low surface temperatures are more difficult to manufacture and do not even have PTC characteristics.

The working voltage is 3.7V~420V, both AC and DC are acceptable. When the working voltage is low, the PTC's normal temperature resistance is small, the resistance-temperature change rate is also relatively small, and the constant temperature temperature accuracy is worse; In addition, at low voltages, the heating power is small, the heating rate is slow, and it is not even possible to rise to a higher temperature.

From the perspective of safety and reliability, PTC heaters generally have higher safety than traditional electric heating wires, high insulation voltage resistance, relatively small leakage current and relatively stable. In some applications, the use of traditional heating wire can not pass the safety certification, and the PTC heater can pass the safety certification, so PTC can be used in places with high safety requirements. However, not all manufacturers' PTCs, all PTCs, will meet the requirements for safety, so we must choose a high quality PTC production plant.

PTC is used for solid heating, the main safety and reliability issues:

(1) PTC ceramic breakdown and burning, resulting in short circuit, burning insulation layer;

(2) The insulating layer breaks down and leaks electricity to make the shell charged.

From the cost point of view, a small area of constant temperature heating, PTC heater can save the temperature control and over-temperature protection part, PTC volume can be done very small, the installation is relatively simple. Constant heating of large heating area, using PTC heater to heat the temperature more uniform. PTC thermostat heaters last several times longer than conventional heater heaters. The use of PTC also saves life and maintenance costs.